Modern steering systems are becoming more complex as vehicles shift toward electrification and autonomy. From steer-by-wire control to torque feedback, precision and timing now define how the car feels on the road. Getting accurate position data fast enough has been a growing challenge, and traditional magnetic or single-channel inductive sensors are beginning to hit their limits.

Modern steering systems are becoming more complex as vehicles shift toward electrification and autonomy. From steer-by-wire control to torque feedback, precision and timing now define how the car feels on the road. Getting accurate position data fast enough has been a growing challenge, and traditional magnetic or single-channel inductive sensors are beginning to hit their limits.

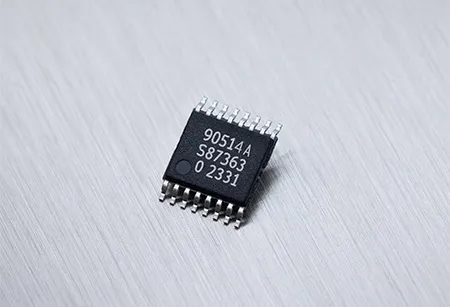

To address this, Melexis has developed the MLX90514, a new inductive position sensor that reads two coil sets at once and processes differential or vernier angle data directly on the chip. Instead of relying on two separate ICs or external computation, the device handles both channels internally, reducing system load and improving timing accuracy.

Dual-Channel Sensing Made Simple

At its core, the MLX90514 is designed for steering torque feedback, steering angle measurement, and rack motor control. It was built to simplify designs that previously needed multiple sensors to get synchronized readings. Both channels operate in real time, so the sensor can calculate angle data with zero latency between them. In steering or torque control systems, that level of synchronization directly affects responsiveness and safety.

In many cases, the device replaces older two-chip setups with a single integrated IC. That means fewer components, shorter wiring, and easier safety validation. It also helps reduce board space, which is useful in compact steering assemblies and other modules where space is already limited.

Built for Flexibility

The MLX90514 supports a range of communication interfaces to fit different setups. SENT, SPC, and PWM outputs make it suitable for standalone modules, while SPI is available for embedded applications. The SENT and SPC outputs can transmit a 24-bit payload, enough for two synchronized 12-bit channels.

An extra input lets the chip accept PWM data from an external sensor, such as a magnetic encoder. Engineers can use this to combine multi-turn or torque information within the same device, turning it into a more complete position-sensing platform rather than just another single-purpose IC.

Compact and Safe by Design

Melexis designed the MLX90514 to work with small coil structures, which allows for tighter PCB layouts and more compact sensor assemblies. The device supports ASIL D compliant systems as a Safety Element out of Context (SEooC), making it suitable for safety-critical automotive designs like steering and chassis control.

Its ability to synchronise data from both channels without external processing means faster, cleaner feedback for real-time control loops, a key advantage for next-generation electric and autonomous platforms.

Why It Matters

Accurate, zero-latency position feedback has become essential for electric and steer-by-wire systems. The MLX90514 gives engineers a way to achieve it without the complexity of dual-sensor arrangements or external processors. In practice, that means tighter integration, better timing, and more predictable control behaviour across safety-critical applications.

Learn more and read the original article on www.melexis.com