High current power stages usually grow more complicated as designers add parallel MOSFETs to handle conduction losses and heat. It works, but every extra device brings more routing, more thermal imbalance to manage and more opportunities for long term reliability issues. Littelfuse is introducing the MMIX1T500N20X4 as a way to avoid that escalation. It is a 200 volt MOSFET rated for 480 amps in a single isolated package, aimed at engineers building compact energy storage and industrial power systems where board space and thermal headroom are already under pressure.

High current power stages usually grow more complicated as designers add parallel MOSFETs to handle conduction losses and heat. It works, but every extra device brings more routing, more thermal imbalance to manage and more opportunities for long term reliability issues. Littelfuse is introducing the MMIX1T500N20X4 as a way to avoid that escalation. It is a 200 volt MOSFET rated for 480 amps in a single isolated package, aimed at engineers building compact energy storage and industrial power systems where board space and thermal headroom are already under pressure.

Shifting Away From Parallel Stacks

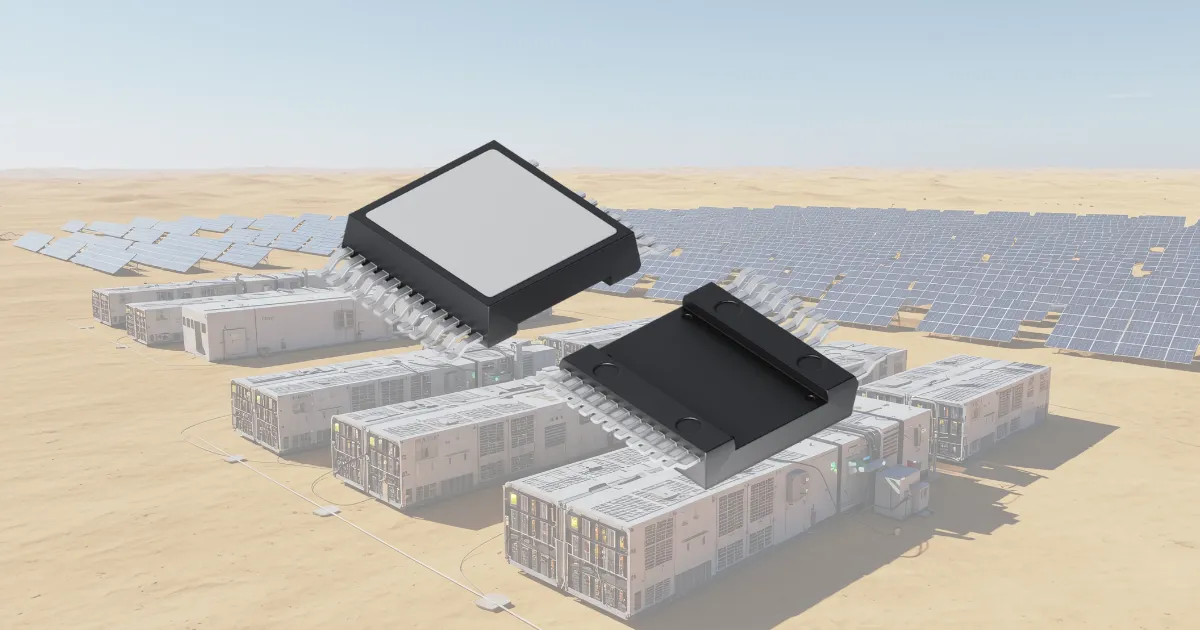

Once a design reaches a certain current level, adding more devices often becomes the only way to spread heat and keep resistance low. The trade off is that gate drive implementation gets harder and current sharing becomes unpredictable during fast load changes. The MMIX1T500N20X4 reduces that dependence by combining an on state resistance of 1.99 milliohms with a current rating that would normally require several devices. In practice this means fewer switching paths and a simpler layout. It also helps avoid the small mismatches in package inductance that show up when multiple devices run in parallel, which can influence transient behaviour more than expected.

Thermal Management Through Package Design

A large part of the device’s capability comes from the SMPD X package rather than the silicon alone. It uses a ceramic isolated structure that supports topside cooling, allowing heat to move directly into a cold plate or spreader instead of relying on copper area on the PCB. For designs already limited by board level thermal spreading, this changes where the bottleneck sits. The junction to case thermal resistance of 0.14 degrees Celsius per watt and 2500 volt isolation rating also position it for systems that need both electrical separation and predictable thermal cycling, such as industrial charging platforms and modular power supplies.

Electrical Behaviour and System Impact

The 480 amp rating is combined with a gate charge of 535 nanocoulombs, which keeps driver power manageable for a device in this current range. Reducing part count can free up board space and lower assembly complexity, especially in battery storage racks where switching hardware usually competes with sensing and safety circuitry. It also removes multiple failure points associated with solder joints and interconnects. For engineers concerned with fast fault response, having a single device means fewer parallel paths that need to stay balanced during sudden load shifts.

Where It Fits and What To Consider

The target use cases span low to medium voltage systems where conduction efficiency matters more than extremely high switching frequency. Examples include DC disconnects in storage modules, industrial process power, drone propulsion stages and charging equipment where compact packaging and predictable thermal behaviour are critical. The SMPD X format aligns with mechanical layouts already used in cold plate systems, so migration does not require major redesign.

Learn more and read the original announcement at www.littelfuse.com