The shift toward integrated lighting modules is accelerating as manufacturers look for simpler ways to move from LED selection to full system design. Instead of purchasing bare emitters and managing their own board layouts, thermal modelling and assembly, many teams now want modules that arrive tested, populated and ready to drop into a luminaire. Cree LED’s new L2 Solutions portfolio speaks directly to that trend by packaging its well known LED platforms into fully built PCB assemblies designed for both indoor and outdoor use.

The shift toward integrated lighting modules is accelerating as manufacturers look for simpler ways to move from LED selection to full system design. Instead of purchasing bare emitters and managing their own board layouts, thermal modelling and assembly, many teams now want modules that arrive tested, populated and ready to drop into a luminaire. Cree LED’s new L2 Solutions portfolio speaks directly to that trend by packaging its well known LED platforms into fully built PCB assemblies designed for both indoor and outdoor use.

At a time when supply chain uncertainty and design overhead often slow project timelines, this approach gives engineers a way to start closer to the finish line. The idea is not to replace custom luminaires but to remove the friction involved in prototyping and scaling standardized light engines.

Why Integrated L2 Modules Matter for Lighting Engineers

Designing LED boards is rarely the challenge teams set out to solve. The work often involves repeating the same set of decisions: pick the footprint, set LED pitch, validate current density, check thermal paths and manage variations in CCT and CRI. Integrated L2 assemblies simplify that process by offering a known layout built around LEDs that are already well understood and widely deployed across commercial and industrial lighting.

For manufacturers working across multiple product lines, consistency becomes a real engineering advantage. Reusing the same board geometries and LED families helps maintain color uniformity, simplify driver choices and reduce the qualification effort across fixtures. Cree LED’s move to stock standard L2 modules through distribution reflects demand for that type of repeatable building block.

Technical Foundations Behind the L2 Indoor and Outdoor Platforms

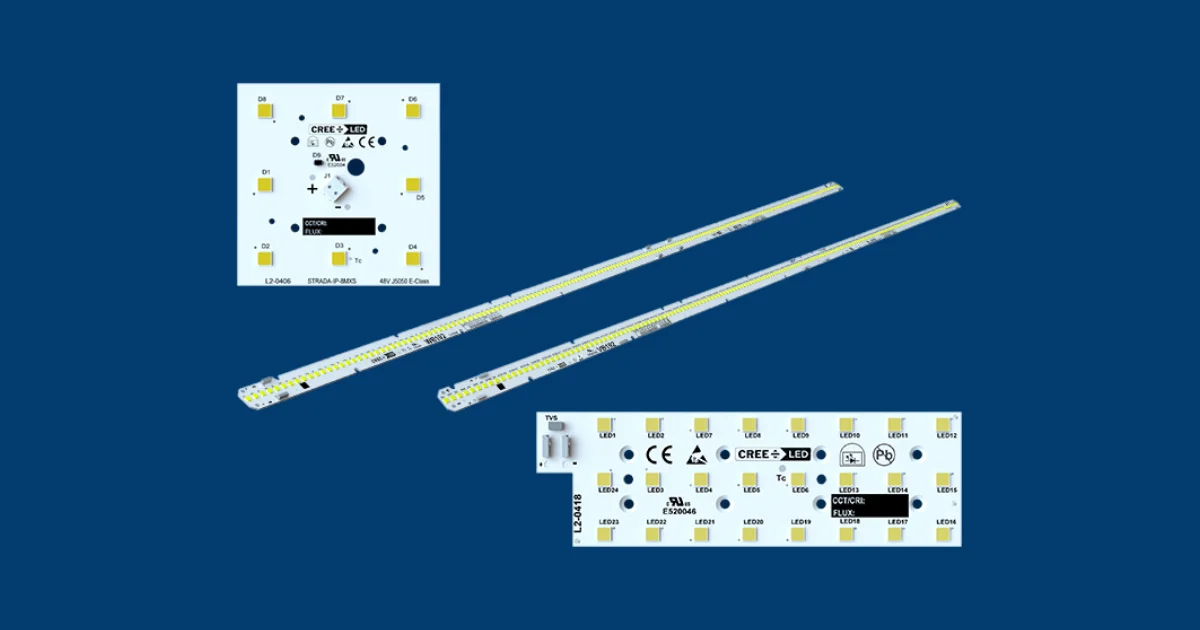

The indoor linear boards use the company’s J Series 2835 LEDs with several LED count options and CCT ranges spanning 3000K to 5000K in both 80 and 90 CRI. This combination targets troffers, linear strips and commercial luminaires where efficacy and color quality both matter. The pitch and board formats are tuned for uniform illumination rather than peak intensity, which helps designers focus on optical and thermal integration instead of emitter layout.

The outdoor arrays use J Series 5050 LEDs, selected for higher drive currents and robustness in environments exposed to wider thermal swings and weather. CCT options drop as low as 2700K, reflecting the growing requirement for warmer outdoor installations that reduce glare and light pollution. Using 5050 LEDs also makes it easier to meet lumen targets in applications like area lighting, wallpacks and floodlights without expanding board size.

A key detail across both product groups is supply chain stability. By building the assemblies in multiple global locations, Cree LED enables manufacturers to source the same board design from different regions without requalifying a new supplier. That type of redundancy has become increasingly valuable as lighting programs scale internationally.

Custom L2 Modules for High Volume Programs

Standard modules suit many applications, but there are still situations where mechanical constraints, thermal targets or optical requirements demand custom layouts. For those cases, Cree LED offers bespoke L2 assemblies built from its XLamp and J Series platforms. The difference here is the access to engineering support and the opportunity to tune board geometry, LED selection and electrical characteristics to the exact needs of a luminaire family.

For high volume manufacturers, designing once and producing at scale with a single supplier helps reduce long term risk. Cree LED has leveraged its position in LED development to support custom solutions for years, and this formal L2 portfolio extends that model to more customers.

What This Means for the Future of LED System Design

As LED performance continues to improve incrementally, much of the differentiation in lighting products now comes from optics, thermal design and control systems rather than the emitters themselves. L2 assemblies fit into that evolution by letting designers focus on the parts of the luminaire that define user experience and application performance.

For engineers, the practical value lies in cutting down the time spent on routine board tasks and relying on LED platforms that behave predictably from prototype to production. Standard modules help accelerate entry level products, while custom assemblies support high end fixtures that require tighter control of light distribution and thermal behavior.

Learn more and read the original announcement at www.cree-led.com