For years, Nexperia’s discretes and logic parts have been the sort of components engineers rarely worried about. They moved steadily through the supply chain, carried long qualification histories, and seldom created the kind of friction that disrupts production schedules. That sense of predictability is beginning to shift.

For years, Nexperia’s discretes and logic parts have been the sort of components engineers rarely worried about. They moved steadily through the supply chain, carried long qualification histories, and seldom created the kind of friction that disrupts production schedules. That sense of predictability is beginning to shift.

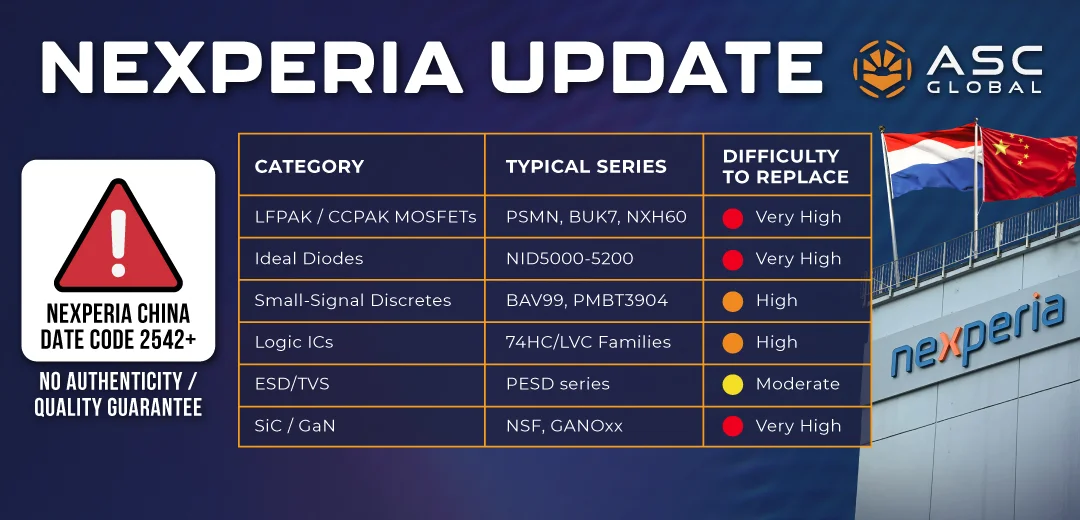

In a new ASC Global analysis examining the widening split between Nexperia’s European headquarters and its Chinese operations, the company outlines early signs that these once dependable building blocks are slipping into a more fragile position. What stands out is that the disruption is not tied to a single factory outage or logistics event, but to the slow accumulation of governance and sourcing issues that now intersect directly with automotive and industrial supply chains.

How a Governance Breakdown Became a Component Risk

What makes this situation unusual is that the technical risk emerges from internal control rather than external shocks. Nexperia B.V. halted the flow of European wafer material to its Dongguan assembly site, and reports suggest that the Chinese operation continued production using domestic wafers. In practice, this creates a split in provenance that engineers cannot treat lightly. Automotive grade components are qualified against specific wafer processes and assembly behaviors that must remain consistent over time. When the manufacturing path starts to split, the device may look identical on the outside, but engineers cannot assume the silicon underneath behaves the same way. The qualification data attached to earlier batches no longer tells the full story, and that uncertainty carries real consequences for systems that depend on predictable long term behavior.

Why Process Divergence Affects Field Reliability

In real systems, discrete semiconductors often sit behind broader functional blocks and are trusted to behave predictably across long life cycles. A change in wafer origin or material stack can influence switching behavior, leakage paths, temperature drift, surge tolerance, and long term stability. These effects may not appear in quick acceptance tests but reveal themselves during extended thermal cycling or in high duty environments found in automotive control modules and industrial machinery. One detail worth noting is that the automotive sector depends heavily on parts that carry AEC Q101 qualification, and that qualification is tied to the stability of the original manufacturing process. Devices that follow an alternative route, even if electrically similar at first glance, fall outside that chain of data. For engineers, that lack of continuity introduces a verification burden that is costly and time consuming.

Procurement Challenges as Validated Inventory Compresses

ASC Global’s assessment highlights that several Tier 1 suppliers have already begun restricting intake of China sourced lots until extended verification is complete. This has pushed demand toward inventory produced in facilities where the manufacturing path is fully controlled, most notably Malaysia and the Philippines. The pressure is not coming from a lack of total output. It is coming from the smaller pool of parts that can be traced cleanly from wafer to final package. That shift is already changing how buyers plan their schedules, since components that were once easy to secure now require earlier decisions to avoid gaps later in the build cycle.

What Teams Across the Supply Chain Should Watch Through 2026

Nexperia has begun moving more of its production toward facilities that remain fully aligned with its headquarters, and that shift will take time to settle. As this rebalancing plays out, availability is likely to fluctuate as global output redistributes across regions with different levels of oversight and qualification history. This creates a planning environment where organizations involved in automotive and industrial electronics need to look closely at how they qualify routine discretes and logic devices. These components are small, widely used, and often treated as interchangeable, yet they carry long life cycle expectations that depend on a stable and well understood manufacturing path. As the production landscape adjusts, the more practical view is that sourcing strategies should evolve alongside it. In many cases, the smallest devices in a system have the greatest influence on whether production schedules stay predictable or face unexpected friction.