When it comes to wiring harnesses in heavy-duty vehicles, reliability is everything. Construction machinery, agricultural equipment, and commercial trucks all rely on harnesses that not only survive harsh conditions but also handle complex branching to power sensors, lighting, and auxiliary systems. Traditionally, those branches have been made by splicing wires together with adhesive-lined heat-shrink tubing. The method works, but it brings problems: uneven resistance, weak ingress protection, and bulkier harness trunks that are harder to route through tight bodywork.

When it comes to wiring harnesses in heavy-duty vehicles, reliability is everything. Construction machinery, agricultural equipment, and commercial trucks all rely on harnesses that not only survive harsh conditions but also handle complex branching to power sensors, lighting, and auxiliary systems. Traditionally, those branches have been made by splicing wires together with adhesive-lined heat-shrink tubing. The method works, but it brings problems: uneven resistance, weak ingress protection, and bulkier harness trunks that are harder to route through tight bodywork.

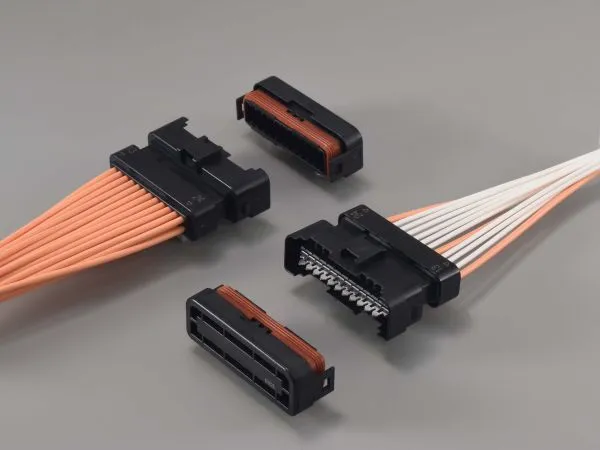

JAE believes it has a better answer. The company’s new HB07 Series waterproof branch connectors eliminate the need for splicing, providing consistent resistance and IP68 waterproofing while keeping harness bundles slim enough to route cleanly through a vehicle frame.

Flexible Configurations Built In

The HB07 is offered in 12-position and 24-position versions, with the ability to cut shorting terminals to define exactly how branches split. That means engineers can configure anything from a simple one-to-two split to more complex multi-line branches inside a single connector. This flexibility reduces the need for custom splices in the field and helps standardise harness production.

Clips can be attached in either orientation, letting the connector be mounted securely without tying it directly into the harness trunk. That makes for easier assembly and maintenance, while also preventing the harness from thickening unnecessarily around splice points.

Designed for Harsh Environments

The HB07 has been tested beyond basic sealing. It carries an IP68 rating and can withstand immersion at depths up to two metres. Validation also included vibration, salt mist, ozone, and high-pressure spray testing — the kinds of conditions common to vehicles that operate in mud, dust, and shifting weather.

Key Specs at a Glance

- Rated voltage: 250 V DC

- Current capacity: 13 A (1.25 mm²), 10 A (0.85 mm²), 7.5 A (0.5 mm²)

- Total current: 40 A max at branch merge point (25 °C ambient)

- Wire range: 0.5–1.25 mm² (AWG #20–#16), insulation Ø1.5–2.9 mm

- Positions available: 12 or 24

- Operating temperature: –55 °C to +125 °C

- Materials: PBT housings with silicone seals, copper alloy contacts

More Than Just Vehicles

Although the connector was developed with machinery and vehicles in mind, JAE also highlights industrial applications. In equipment that requires outdoor branching, the HB07 can even replace terminal blocks, providing the same circuit distribution but with robust waterproofing.

A Cleaner Way to Build Harnesses

Splicing has long been a weak point in harness design, adding both complexity and potential failure points. The HB07 Series takes that challenge off the table, giving engineers a tool that simplifies harness routing, improves sealing, and ensures repeatable performance. For vehicles and systems that operate in unforgiving conditions, that combination could be a real step forward.

Learn more and read the original announcement here.