Automotive wiring has become one of the biggest bottlenecks in modern vehicle development. As OEMs move from distributed ECUs to zonal architectures, the amount of power, signal and data wiring keeps rising while packaging space stays tight. Molex’s latest MX DaSH Modular Wire to Wire Connectors are designed to ease that pressure by bringing power and signal into a single configurable interface that can adapt to different vehicle platforms without rewriting the entire harness strategy.

Automotive wiring has become one of the biggest bottlenecks in modern vehicle development. As OEMs move from distributed ECUs to zonal architectures, the amount of power, signal and data wiring keeps rising while packaging space stays tight. Molex’s latest MX DaSH Modular Wire to Wire Connectors are designed to ease that pressure by bringing power and signal into a single configurable interface that can adapt to different vehicle platforms without rewriting the entire harness strategy.

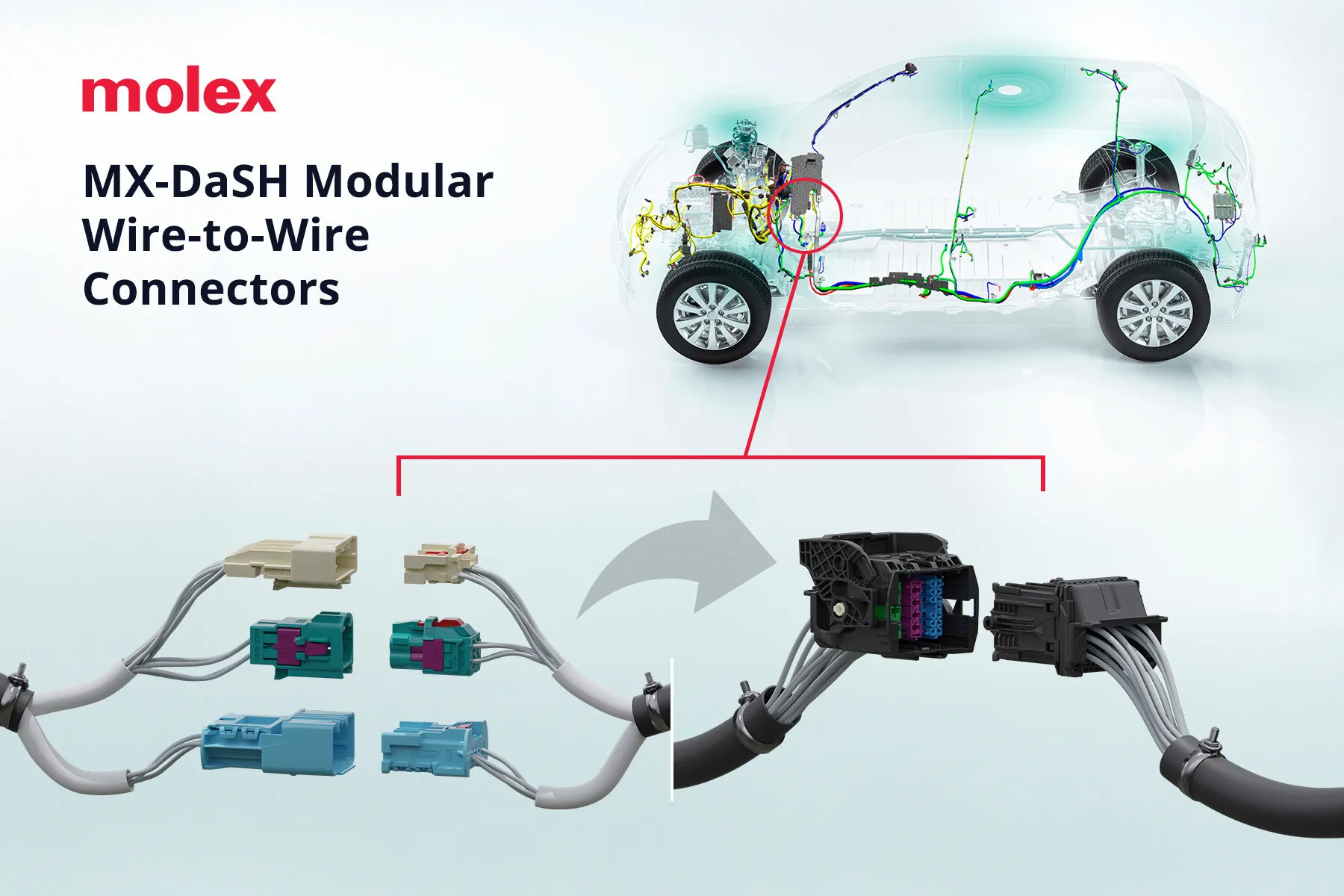

Modular Connectivity For Evolving Vehicle Architectures

The move to zonal systems forces engineers to condense more functionality into a few high content connection points. Molex approaches this with a cartridge based system that allows power and signal terminals to sit in the same housing, reducing the number of separate connectors in a harness. For engineers, this matters because each removed connector means lower weight, fewer part numbers and a clearer architecture path when functions shift between zones. In practice, a single modular connector can replace clusters of legacy interfaces across instrument panel junctions, body to cabin transitions and seat modules. The design also supports quick reconfiguration, which reduces tooling cycles and speeds up feature integration on new model years.

Technical Structure And Cartridge Options

Each MX DaSH Modular Wire to Wire Connector uses an unsealed hybrid platform built from swappable cartridges. Engineers can mix CTX50 signal cartridges alongside 1.20 mm, 2.80 mm, 4.80 mm or 6.30 mm power cartridges within one housing. Maximum pin count reaches 70 circuits, while individual cartridges range from 26 circuits for CTX50 to 3 circuits for the larger power formats. This structure cuts down unique part variation and supports both high density signal routing and mid power distribution inside the same connector body. Positive locking features, blade stabilisation and internal vibration resistant geometry help preserve reliability in areas of the vehicle subject to motion, temperature cycling and mechanical shock.

Integration Considerations In Zonal Systems

Zonal architecture design typically requires balancing localised power distribution with the rising demand for high speed signal paths linking sensors, domain controllers and infotainment hardware. MX DaSH Modular connectors offer a building block approach for this. Engineers can add or replace cartridges to accommodate new features without redesigning the entire wiring harness, which is valuable when vehicle platforms share electrical backbones. The connector layout also supports automated assembly, which reduces labour cost while improving precision. This makes it easier to scale production for mid cycle feature updates where harness changes would historically require manual intervention.

Implications For Future Vehicle Platforms

The automotive market is shifting toward platforms that stay in production for longer but evolve digitally through software and feature packs. A modular connector system aligns well with that direction, since it allows electrical updates without full harness regeneration. Molex is already seeing early adoption in China for MY26 vehicles, driven by strict cost controls and fast design cycles, and additional uptake in North America and Europe is expected as OEMs move their MY28 platforms toward zonal architectures. As sensor density rises and high speed links proliferate, hybrid connectors that unify power and signal paths will likely become standard in areas that currently rely on several separate components.

Learn more and read the original announcement at www.molex.com