TE Connectivity Unveils Inside Device Connectivity Solutions for Automotive Modules

Modern vehicles put extreme demands on internal electronics. As features like ADAS, zonal control, and electrification ramp up, ECUs must integrate more functions in tighter spaces. Connectors inside these modules must carry power, signals, and ground in environments with vibration, EMI, temperature swings, and contamination. Traditional designs often fall short when designers push density, reliability, and compactness simultaneously.

Modern vehicles put extreme demands on internal electronics. As features like ADAS, zonal control, and electrification ramp up, ECUs must integrate more functions in tighter spaces. Connectors inside these modules must carry power, signals, and ground in environments with vibration, EMI, temperature swings, and contamination. Traditional designs often fall short when designers push density, reliability, and compactness simultaneously.

TE’s In-Device Connectivity Portfolio

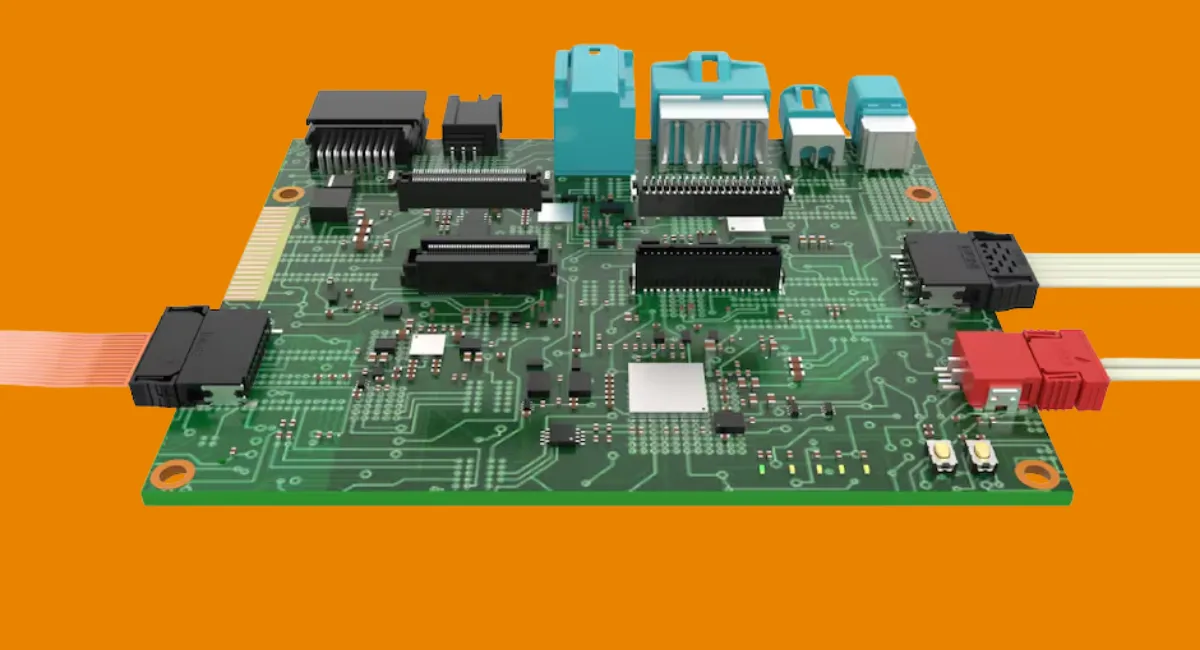

TE Connectivity’s new inside device connectivity line addresses those exact pressures. The portfolio offers solutions across board-to-board, wire-to-board, flex-to-board, and wire-to-wire form factors. These are built for signal integrity, mechanical tolerance, and compact packaging inside automotive electronic modules.

From TE’s materials: the portfolio supports pitches from 0.4 mm up to 10.16 mm and pin counts as high as 180. Wire-to-board variants in the range handle currents up to 45 A, while board-to-board paths go up to 18 A. TE also highlights that its internal connectors are designed for harsh environmental conditions: vibration, heat, humidity, and EMI exposure.

The TE in-device page also gives use-case context. These connectors are used in EV battery and battery management, onboard chargers, power conversion modules, ADAS sensors like radar and LiDAR, and high-performance compute modules. Because these connectors lie inside modules, they reduce footprint, wire lengths, and assembly complexity.

Why This Matters

If you are designing zonal ECUs, module electronics, or embedded systems, this portfolio is relevant. You’ll look at trade-offs among pitch, pin count, current capability, and EMI performance. Having connector choices with high current density and mechanical robustness in tight module spaces helps reduce wiring cost and thermal stress.

Because these connectors are internal (not external vehicle harness), they act as the final link inside modules. The better their mechanical and EMI design, the fewer signal losses or failures downstream.

Learn more and read the original article on www.te.com