TDK has expanded its i7A series with new non-isolated DC-DC buck converters that push the limits of what can be delivered from a 1/16th brick footprint. The latest models reach 1000 W and support output currents of 60 A and 80 A, which is a substantial increase over the earlier versions. For engineers working on compact, high-density power supplies, this level of performance in such a small form factor opens up new design options in industrial, medical and communications systems.

TDK has expanded its i7A series with new non-isolated DC-DC buck converters that push the limits of what can be delivered from a 1/16th brick footprint. The latest models reach 1000 W and support output currents of 60 A and 80 A, which is a substantial increase over the earlier versions. For engineers working on compact, high-density power supplies, this level of performance in such a small form factor opens up new design options in industrial, medical and communications systems.

More Power in the Same Footprint

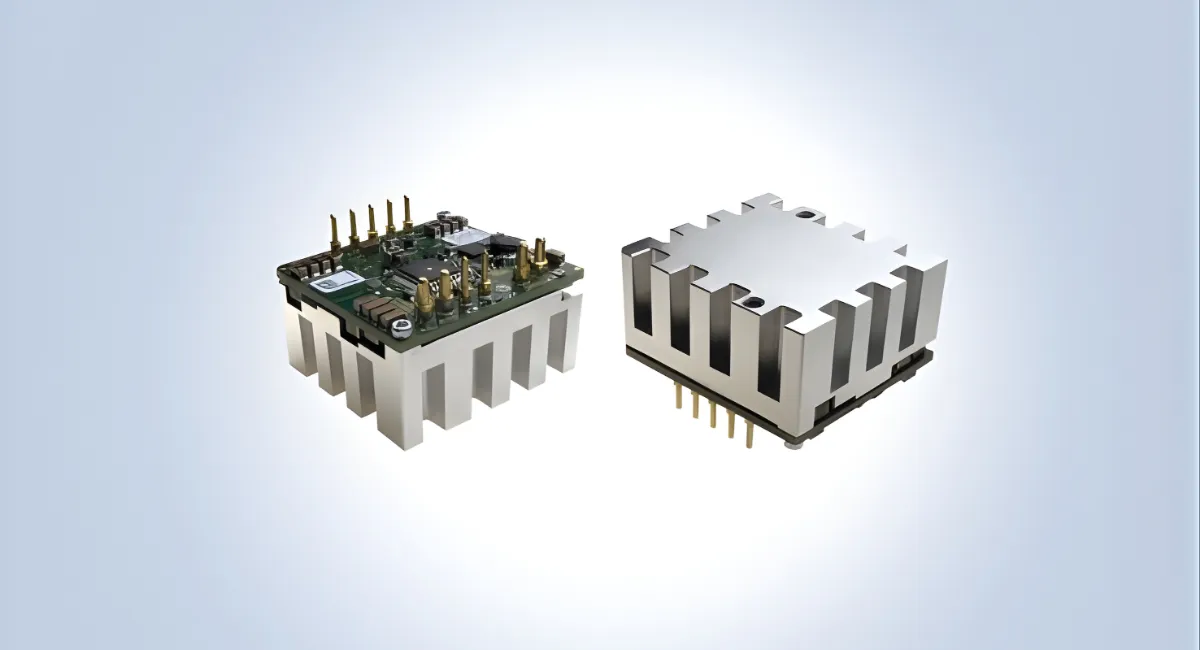

One of the constraints in high-density systems is that footprints are often locked in early, especially in mature platforms or when products must be interchangeable across multiple configurations. TDK’s decision to maintain the 1/16th brick format means engineers can increase available power without changing mechanical layouts. The new models also introduce redundant input and output power pins, which help distribute high currents more effectively across the connector interface. This makes it easier to scale solutions between 400 W and 1000 W while keeping the same board outline.

Despite the higher current levels, the modules weigh only 85 grams. The reduced weight comes from an improved baseplate design that maintains thermal performance without accumulating unnecessary mass. For mobile and weight-limited systems such as drones, test equipment or robotics, this is a practical advantage.

Wide Input Range for Multi-Voltage Systems

The converters operate from 18 V to 60 V and offer an adjustable output from 3.3 V to 28 V. This produces a wide enough window to support everything from 24 V industrial rails to 48 V communications backplanes. Having a broad input and output range also helps streamline bills of materials, since fewer specialised part numbers are needed to cover different configurations across a product family.

The adjustable current limit is useful when dealing with capacitive loads or fault conditions. By reducing peak stress during inrush events or short circuits, designers can protect downstream components and extend system reliability. It also enables parallel operation when redundancy or higher output power is required.

Efficiency and Thermal Management

Efficiency levels up to 99 percent are notable because they reduce both conduction losses and heat generation. In sealed industrial systems, test equipment or outdoor enclosures, every watt of thermal overhead matters. High efficiency combined with a compact footprint and multiple cooling options means the converters can slot into a wide range of thermal environments. The series supports open-frame operation, baseplate cooling and heatsink mounting, which gives engineers flexibility to match the module to their thermal constraints.

Applications Beyond the Typical Brick Converter

The expanded i7A family is positioned for applications that need high reliability and high power density without moving to larger isolated bricks. These include medical equipment, communications infrastructure, robotics, drones and battery-powered systems where size and weight restrictions are strict. The series meets IEC, UL, CSA and EN 62368-1 safety standards and carries CE and UKCA marks, which helps accelerate certification work for end systems.

While many DC-DC modules focus on incremental improvements, the latest additions to the i7A line deliver a noticeable jump in usable power within a known mechanical format. For engineers balancing performance, footprint and thermal constraints, this expansion offers a straightforward upgrade path without revisiting enclosure or PCB layouts.

Learn more and read the original article on www.tdk.com