Sensing accuracy has become a limiting factor in modern office and industrial equipment where materials move faster, tolerances shrink and automated systems need cleaner feedback. Small deviations in label position, feed alignment or object spacing can create cascading faults that slow production. ROHM’s new RPR 0730 reflective sensor is designed for these conditions, offering fast response and precise detection in equipment where optical performance directly affects reliability.

Sensing accuracy has become a limiting factor in modern office and industrial equipment where materials move faster, tolerances shrink and automated systems need cleaner feedback. Small deviations in label position, feed alignment or object spacing can create cascading faults that slow production. ROHM’s new RPR 0730 reflective sensor is designed for these conditions, offering fast response and precise detection in equipment where optical performance directly affects reliability.

High Directionality For Fine Feature Detection

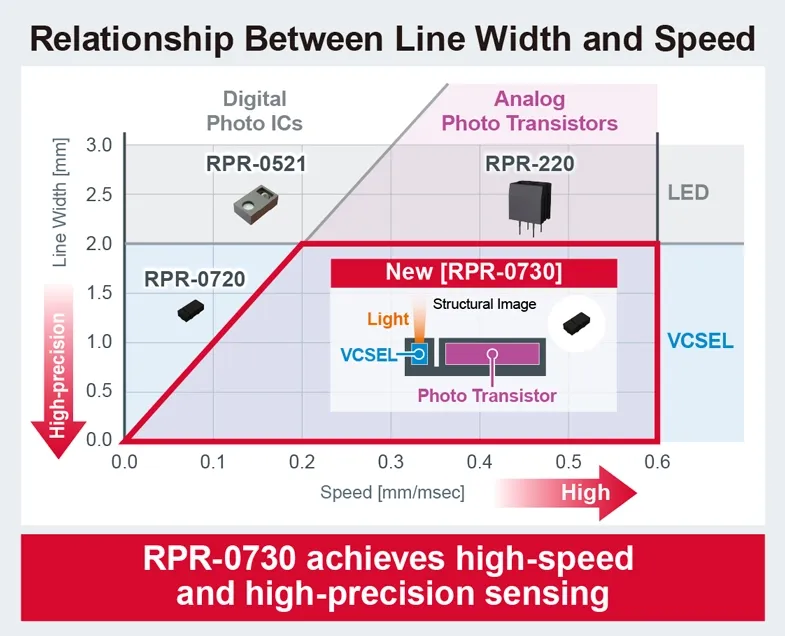

The sensor is built around a 940 nm VCSEL emitter, which is a notable departure from the LED based setups that often struggle with narrow lines or small surface changes. A VCSEL produces a tighter beam, allowing the detector to capture more predictable reflection patterns. This helps in applications like label edge sensing or print line recognition where the difference between a good read and a missed event can be a fraction of a millimetre. With the RPR 0730, ROHM targets line widths down to 0.1 mm, which were previously difficult to register at high speed.

Image credit: Rohm Semiconductor

Image credit: Rohm Semiconductor

Fast Analog Response For Rapid Motion

At the receiving side, the device uses a phototransistor with an analog output rather than a digital thresholding circuit. This choice keeps latency low, giving the sensor a response time around 10 microseconds. In practical terms, a conveyor or printer running at higher throughput can still capture subtle position changes without the detection window collapsing. Engineers working on jam detection, rotational tracking or small object spacing can use the analog output to fine tune system thresholds based on surface reflectivity and ambient conditions.

Stable Operation In Variable Light Conditions

The package uses a light filtering resin to reduce interference from ambient light or sunlight, which is a common failure point for reflective sensors deployed in open machinery or bright environments. Filtering helps maintain consistent behaviour across different installation sites without requiring aggressive shielding or mechanical covers. The 2.0 mm by 1.0 mm by 0.55 mm package makes integration easier in compact assemblies such as miniature conveyors, feed rollers or motor housings where board space is limited.

Integration Into High Speed Equipment

Because the sensor outputs an analog signal, it can be dropped into systems requiring continuous measurement rather than binary object presence. This is relevant in print engines, copiers and compact industrial robots where the control loop benefits from reading small intensity variations. The short detection distance, typically around a few millimetres depending on configuration, fits well with mechanisms that already position sensors close to the target. For engineers migrating from the RPR 0720 digital family, the new device offers a cleaner upgrade path for applications pushing toward higher motion speeds.

Broader Implications For Precision Sensing

As automation continues to move into smaller, faster and more precise systems, optical sensors will increasingly define the accuracy of the control logic behind them. Devices like the RPR 0730 show how improvements in emitters and receivers are enabling detection that keeps pace with mechanical advances. The combination of VCSEL illumination, analog output and small footprint makes this device a strong candidate for next generation office equipment, compact robotics and tightly integrated factory subsystems.

Learn more and read the original announcement at www.rohm.com