USB Type-C connectors take more mechanical abuse than almost any other component in modern electronics. They are plugged and unplugged daily, leveraged by heavy cables, and often damaged long before the rest of the product shows any wear. Yet in most designs, the connector is still treated as permanent. When it fails, the assumption is that the board fails with it.

USB Type-C connectors take more mechanical abuse than almost any other component in modern electronics. They are plugged and unplugged daily, leveraged by heavy cables, and often damaged long before the rest of the product shows any wear. Yet in most designs, the connector is still treated as permanent. When it fails, the assumption is that the board fails with it.

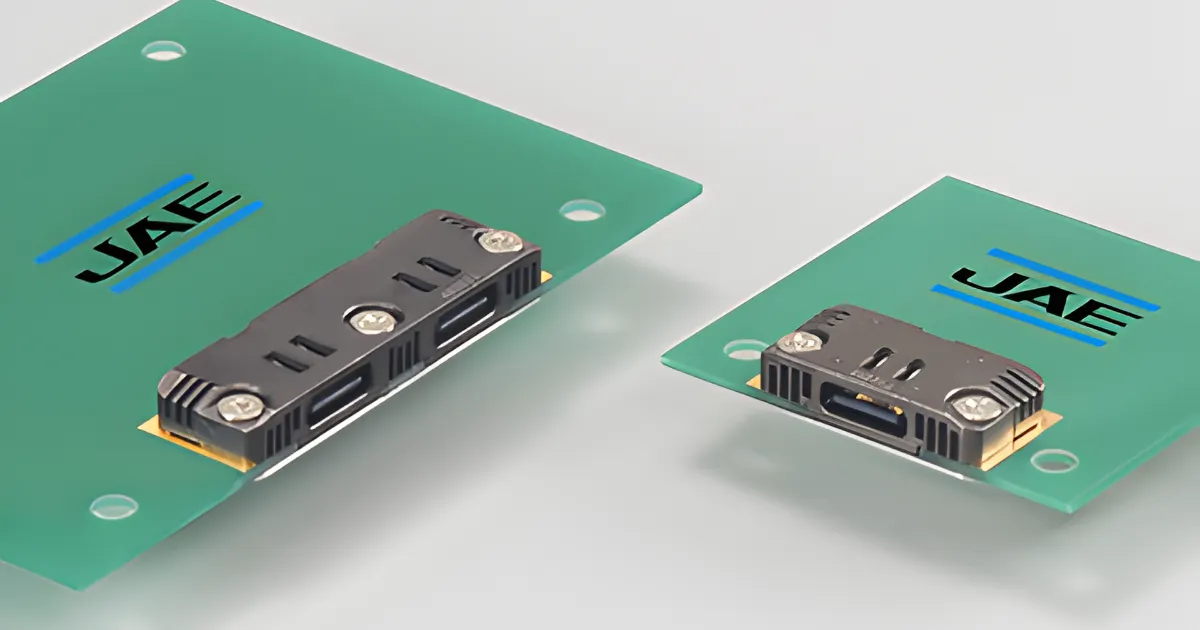

That assumption is becoming harder to defend, both economically and regulatorily. Repairability is no longer a secondary consideration, particularly in Europe, where products are increasingly expected to survive routine wear without being written off. JAE is responding to that pressure with a compression-mount USB Type-C receptacle in its DX07 Series, designed to be replaced mechanically rather than desoldered.

Why USB-C Ports End Product Lifetimes Early

From an electrical standpoint, surface-mount USB-C connectors work well. Mechanically, they are a common failure point. Once the shell loosens or the contacts wear, repair usually means hot-air rework, specialist tools, and a non-trivial amount of time. In many consumer and commercial products, that repair is simply not attempted.

The result is familiar. A single worn connector leads to full board replacement or product disposal. As repairability regulations begin to look beyond documentation and into physical serviceability, that failure model becomes a design liability rather than an accepted trade-off.

What Compression Mounting Changes in Practice

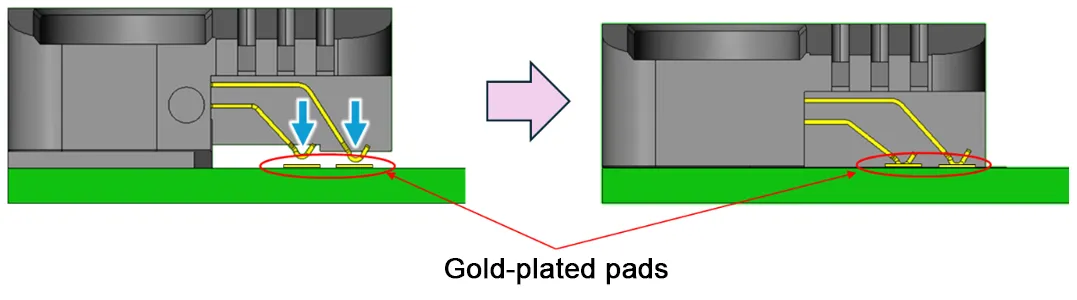

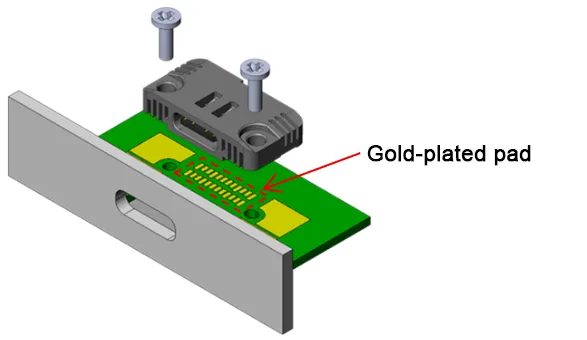

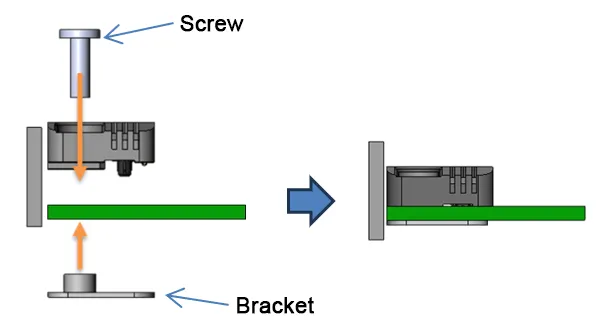

The DX07 compression-type receptacle alters how the connector interfaces with the board. Instead of relying on solder joints for both electrical connection and mechanical retention, the connector uses compression coupling with gold-plated pads. The assembly is secured mechanically and can be removed using a standard screwdriver.

From a system perspective, this changes how failure is handled. The connector becomes a replaceable wear item rather than a terminal fault. There is no rework station, no thermal stress on surrounding components, and no requirement to scrap a functioning PCB because a single interface has reached end of life.

From a system perspective, this changes how failure is handled. The connector becomes a replaceable wear item rather than a terminal fault. There is no rework station, no thermal stress on surrounding components, and no requirement to scrap a functioning PCB because a single interface has reached end of life.

Mechanical Strength Still Matters

A replaceable connector only makes sense if it survives normal use. JAE addresses this with a metal injection molded shell designed to absorb mechanical stress from repeated insertion, cable strain, and incidental impact. This is particularly relevant in laptops and docking stations, where connectors are frequently loaded in directions the USB specification never intended.

Electrically, the DX07 series aligns with current USB-C expectations. The connectors support USB4 Version 2.0 data rates and USB Power Delivery EPR up to 240 W, meaning repairability is not achieved by stepping back from performance or power capability.

A Small Change With System-Level Consequences

What stands out here is not the regulatory alignment itself, but where the design choice is made. Repairability is addressed at the connector interface, not deferred to service policy or documentation. The ability to remove and replace the port is inherent in the hardware.

For engineers, this introduces a different way of thinking about failure. Instead of treating the USB-C connector as a weak point to be reinforced indefinitely, it becomes a controlled wear component that can be serviced when it eventually fails. In products where the connector is the first thing to wear out, that distinction can decide whether a device is repaired or discarded.

Learn more and read the original announcement at www.jae.com