Design teams working on powered tailgates, sliding doors or seat actuation often run into the same constraint. As more motors are added to a vehicle’s body systems, the wiring harness grows, microcontroller pins disappear quickly and bus traffic starts to become a bottleneck. Managing several brushed DC motors at once usually forces a tradeoff between simplicity, responsiveness and communication overhead. Toshiba’s new TB9104FTG gate driver enters that environment with an approach that moves much of the coordination away from the MCU and onto the driver itself.

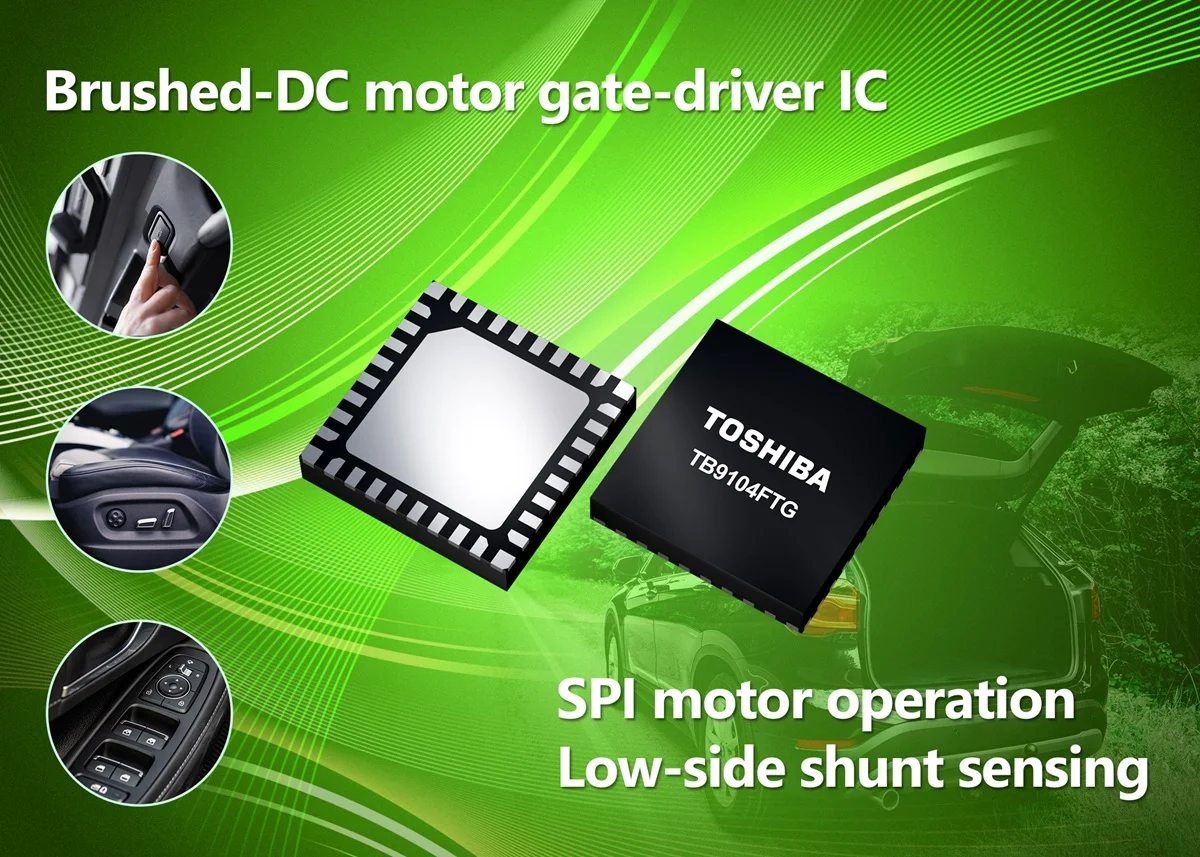

Design teams working on powered tailgates, sliding doors or seat actuation often run into the same constraint. As more motors are added to a vehicle’s body systems, the wiring harness grows, microcontroller pins disappear quickly and bus traffic starts to become a bottleneck. Managing several brushed DC motors at once usually forces a tradeoff between simplicity, responsiveness and communication overhead. Toshiba’s new TB9104FTG gate driver enters that environment with an approach that moves much of the coordination away from the MCU and onto the driver itself.

SPI Control Reduces Pin Count And Communication Load

The detail that changes system behavior is the decision to let the motor be commanded directly over SPI rather than relying only on standard PWM input lines. In practice, this means multiple gate drivers can sit on the same SPI bus and receive motor control instructions without occupying extra MCU pins. The MCU can issue a single rotation command to initiate movement, while the driver handles its own PWM clock generation internally. As a result, the bus sees fewer transactions and pin pressure on the host controller decreases. This can simplify both the wiring harness and the board level architecture in body control modules.

Gate Drive Architecture Built For Multiple Motor Modes

The driver supports conventional single motor control through an external H bridge, but it can also operate two brushed DC motors when used in a dual half bridge configuration. This gives automotive designers more flexibility when distributing load paths across a car’s door or seat actuation mechanisms. The device is housed in a 5.0 by 5.0 millimeter VQFN32 package with an exposed pad. That pad plays a practical role once high current paths and switching losses begin to warm the system, because it gives the PCB a way to conduct heat out of the package when paired with external MOSFETs.

Current Feedback And Protection For High Current Loads

One detail worth noting is the integrated current sense amplifier. Body motors can stall or bind when mechanisms encounter resistance, and the resulting current spike can be sudden. The amplifier feeds real time information back to the MCU so the system can shut down the drive path before the external MOSFETs overheat or the wiring suffers. The TB9104FTG also monitors for low voltage, charge pump overvoltage, thermal conditions on the die, external MOSFET faults and SPI communication issues. This collection of feedback paths helps support fault handling strategies in applications that face mechanical loads and user interaction.

Automotive Reliability And Environmental Range

The device targets AEC Q100 Grade 1 qualification and is designed for operation from minus 40 degrees Celsius to plus 125 degrees Celsius. This range supports placement inside door modules, tailgate assemblies and seating systems where ambient conditions shift quickly and thermal gradients rise during extended motor operation. As manufacturers continue to electrify body mechanisms and increase the number of small motors in each vehicle, components that consolidate control and reduce wiring overhead become more important.

For engineers, the takeaway is that the TB9104FTG blends gate drive control, protection and communication efficiency into a package suited for the next wave of automotive body electronics. It simplifies the interface to the MCU while giving designers more room to manage high current motors within tight thermal and mechanical limits.

Learn more and read the original announcement at www.toshiba.com